Manage inventory effectively with a monitoring service

Industrial processes consume a lot of materials. In order to effectively manage and monitor the operation of the plant, it’s important to monitor inventory as accurately as possible. For example, the inventory status of raw materials is crucial for the continuity of the process. Yet in industry, the amounts of raw materials in stock are often approximated through visual inspection.

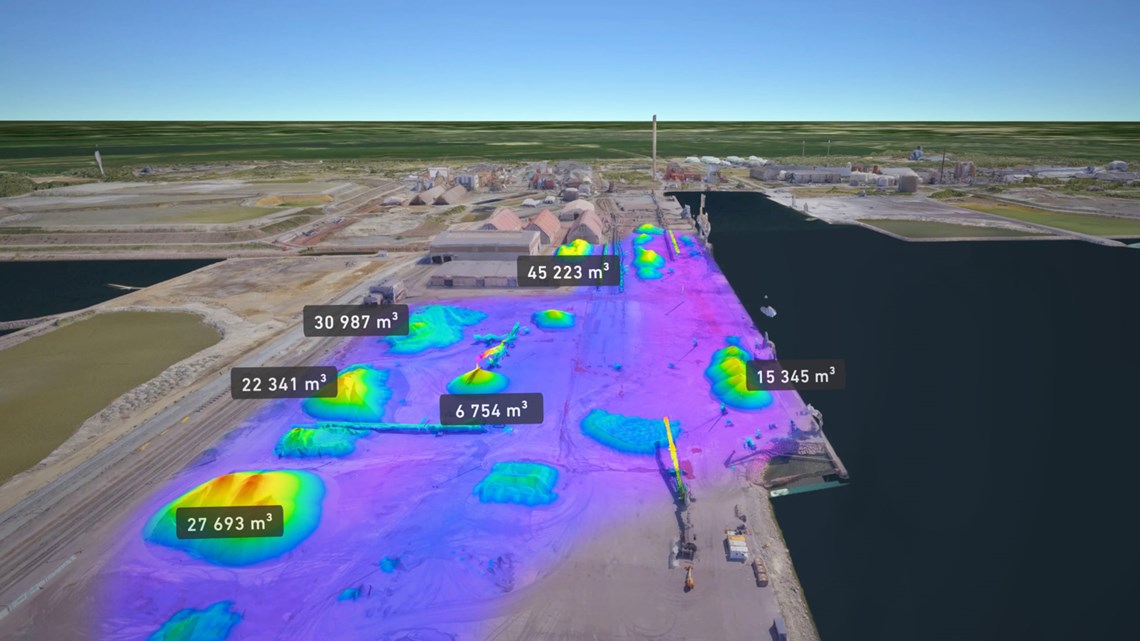

3D imaging and mapping methods provide reliable and documentable information about the inventory situation.

Reliable stock monitoring ensures the smooth running of production processes

Having reliable information about the current stock situation ensures the continuity of the production process. A documented inventory situation also facilitates and enhances monitoring and reporting. Regular inventory and volume calculation of stockpiles can affect the efficiency of the plant's operations: there is no extra in the warehouse, only what is needed for efficient operation.

Get the exact stock situation with 3D imaging and mapping methods

Using 3D imaging and mapping methods, we measure the piles in stock and calculate the volumes of the piles. You will receive a visual report of the results. The report can be broken down by volume and substance by the heap, so the inventory is accurate and reliable.

Indoor storage spaces are mapped using the laser scanning method and outdoor storage fields are mapped using drone mapping. Laser scanning and drone mapping are suitable for sites where the need for mass computing is weekly, monthly or quarterly.

Fixed systems can also be built in warehouses. With the help of these systems, the mass calculation can be carried out very frequently, for example, every hour.

Visual results immediately create an overall understanding of the inventory situation. We customize the data to be reported as needed and are responsible for cost-effective inventory. Our expertise in machine vision solutions makes us a reliable partner as a service provider for fixed monitoring systems.

Mass calculation of heaps of raw materials and intermediate stocks using mapping methods brings certainty to the process and enables you to lead with data. Contact us and we will show you examples of successful projects.

Contact us

Contents you might be interested

The arbitral tribunal has confirmed Crayfish BidCo Oy’s redemption right over Caverion Corporation’s minority shares and trading in the Caverion shares will be suspended

The arbitral tribunal has confirmed Crayfish BidCo Oy’s redemption right over Caverion Corporation’s minority shares

Read more...

Pasi Päivärinta appointed as interim CFO of Caverion

Pasi Päivärinta appointed as interim CFO of Caverion

Read more...

Current digital status of a building is the basis for its future capabilities

In the future, more intelligence will be required from real estate. As our society shifts towards the increased use of renewable energy sources, the availability of energy will fluctuate. Read more in our blog!

Read more...